Aviation

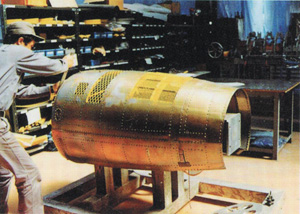

Air cargo containers

Air cargo containers are vital for the transport of air cargo and passenger luggage and must be as lightweight and strong as aircraft structures. Hayakawa Industries is the leading domestic maker of air cargo containers. We handle the entire production process from raw materials to finished product.

Stringers

Stringers (or longerons) form the "skeleton" of fuselage of airplanes and support the skin of the aircraft in the longitudinal direction. These important components are produced using our advanced engineering abilities.

Helicopter engine covers

We produce engine covers that protect the engine components of helicopters.

Due to the thinness of the materials and their curved shape, their manufacture requires expert riveting technology.

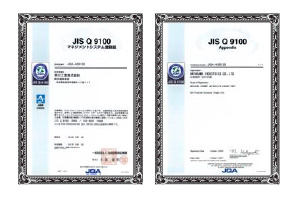

◆JISQ9100

We have acquired JISQ9100 certification, a standard for the Aerospace supply chain, and keep improving of quality assurance.

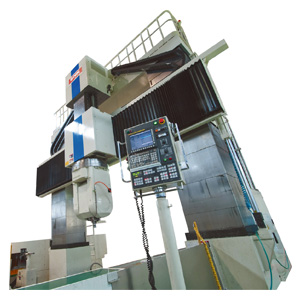

Major production equipment

Main equipment used to manufacture aviation components.

Part manufacturing Sheet metal machining Bending equipment

- 6m brake press

- Used to form large metal sheets such as airplane flap skin and more.

Part manufacturing Machining

- Double column type machining center

- The 5-axis double column type machining center is used to machine large and long components.

- 3 rollers (aluminum 5m, length 2500)

- The independent lateral driven operation enables taper processing. This system was jointly developed with a roll manufacturer for avionic components.

- Large double column type machining center

-- 2 pallet model - This machining center performs well economically and functionally.

- Horizontal machining center

- This machining center performs well economically and functionally.

- NH6300 Horizontal 4-axis machining center

- This machining center performs well economically and functionally.

- CAD/CAM/CATIA

- We use CAD/CAM/CATIA when designing.