Railway and transportation

High-speed rail components

We manufacture many underfloor components for the Japanese shinkansen high speed rail cars.

The underfloor components for the rapidly moving "bullet trains" are normally kept out of sight, but are required to meet demanding standards of quality while remaining light weight and highly durable.

High speed rail is formed from many constituent parts that come together making a whole, and it is vital to have a manufacturing system that enables production of consistent quality.

Railcar structural components

Hayakawa produces railcar and subway car doors for urban centers including the three largest metropolitan areas in Japan: Tokyo, Osaka and Nagoya. These parts open and close repeatedly and sustain extreme loads and pressure from both inside and outside of the carriage. We are able to support mass production of uniformly high-quality parts.

We produce steel frames for the front of railcars where both hardness and flexibility are desired as well as railcar pilots that remove snow and other obstacles from the rails.

Major production equipment

Main equipment used to manufacture railway and transportation components

Part manufacturing Sheet metal machining equipment

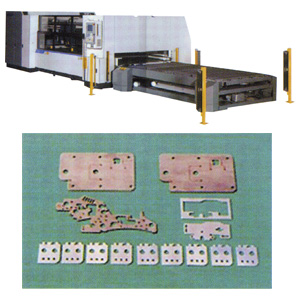

- Laser-Punch composite machine

- Composite machine which has Laser - Punch functions to provide labor-saving system

- Laser cutter

- Cuts carbon steel, stainless steel, aluminum alloys, titanium and other materials freely into a variety of shapes. (Thickness 10mm aluminum sheet cutting possible)

Assembly Welding equipment

- Automatic spot welding machine

- The equipment enables consistent high-quality spot welding